How to Select an Extension Spring? Complete Guide

Century Spring offers the largest inventory of high-grade extension springs in the world. We also produce custom springs made to your exact specifications. To order, shop our selection of stock extension springs or request a quote for custom extension springs.

An Introduction to Extension Springs

All of Century Spring's stocked extension springs are of the constant diameter type with a variety of hook/loop styles. Each spring is wound with an initial tension force which offers a small deflection load for secure installation “holding.” The initial tension is equal to the minimum force required to separate adjacent coils. Unless otherwise noted, Century extension springs are made with either machine hook, or full loop ends.

Note: If the spring needed for your application cannot be found in our inventory, we can fabricate it for you. Simply request a quote.

Extension Spring Design Information

Find the spring’s outside diameter (O.D.) and the length or rate (strength) you require.

- The rate is the load (pounds) it takes to deflect (stretch) the spring one theoretical inch. The rate is linear, i.e., if the rate = 40 lbs./1 in, it would take 10 pounds to deflect it 1/4 inch and 80 pounds to deflect it 2 inches, etc. The initial tension (I.T.) must be overcome before stretching commences.

- The load required to stretch a spring to some point is equal to the sum of the initial tension and the distance it stretched times its rate.

Total Force = I.T. + Deflection x Rate

If the required spring's O.D. and/or length are not important, review the “Maximum Suggested Load” for springs in the size range you think you require. This value is the force created at the “Maximum Suggested Deflection” and includes the initial tension. The suggested maximum deflection and loads listed are for a spring expected to give an average cycle life of around 50,000 cycles. As cycling increases, the maximum load should be decreased in order to support a long service life. For reference, the suggested max deflection is the distance a spring will travel over and above its free length. The use of a fish scale of an appropriate size can be a convenient aid in determining the load required.

If the spring needed for your application cannot be found in our inventory, we can fabricate it for you. Simply request a quote.

Spring Characteristics

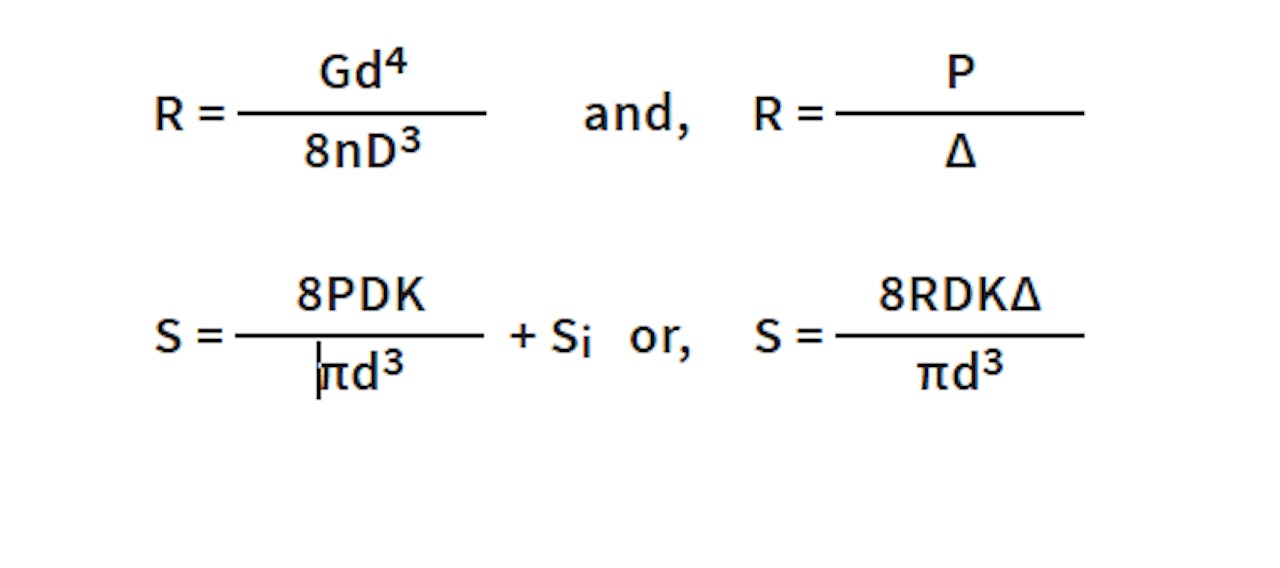

Calculating Extension Rate and Stress

The basic spring extension rate and body-wire stress can be calculated with the following formulae.

Where:

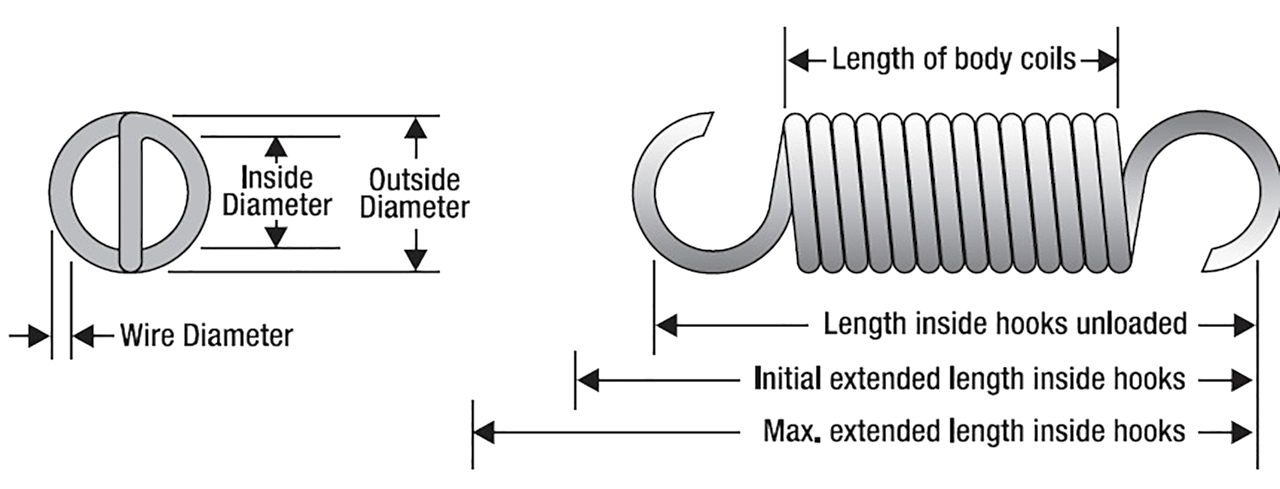

D = Mean diameter, (O.D. - d) inches

d = Wire diameter, inches

G = Modulus (spring steel=11.5×106, stainless10x106)

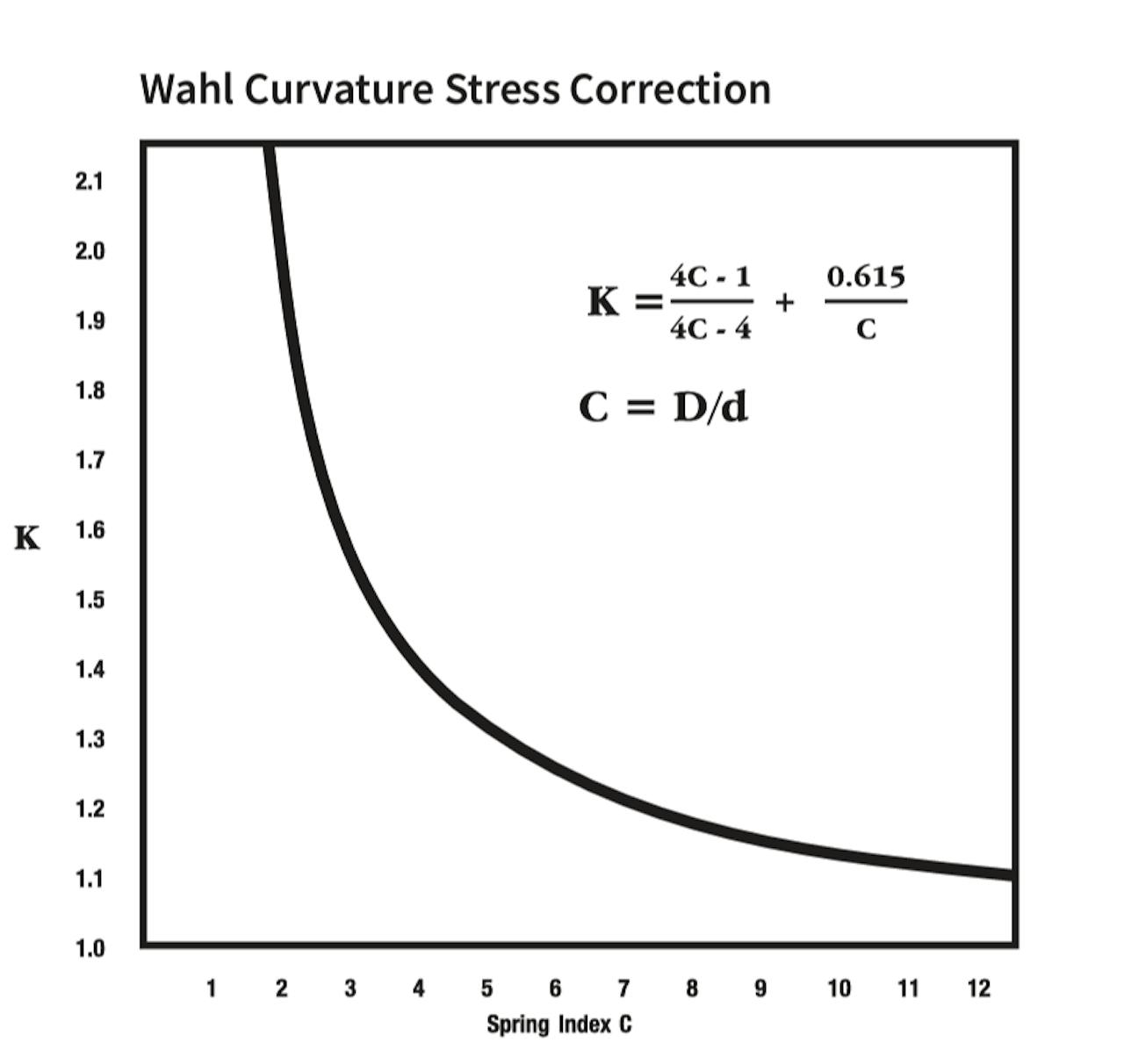

K = Stress correction factor (see next page)

n = Number of coils

P = Applied load, lbs.

R = Rate (constant), lbs./in.

S = Body wire stress, psi

Δ = Deflection (stretch) due to load, inches

π = 3.14

Si = Stress due to initial tension

Finding Spring Stress Rates

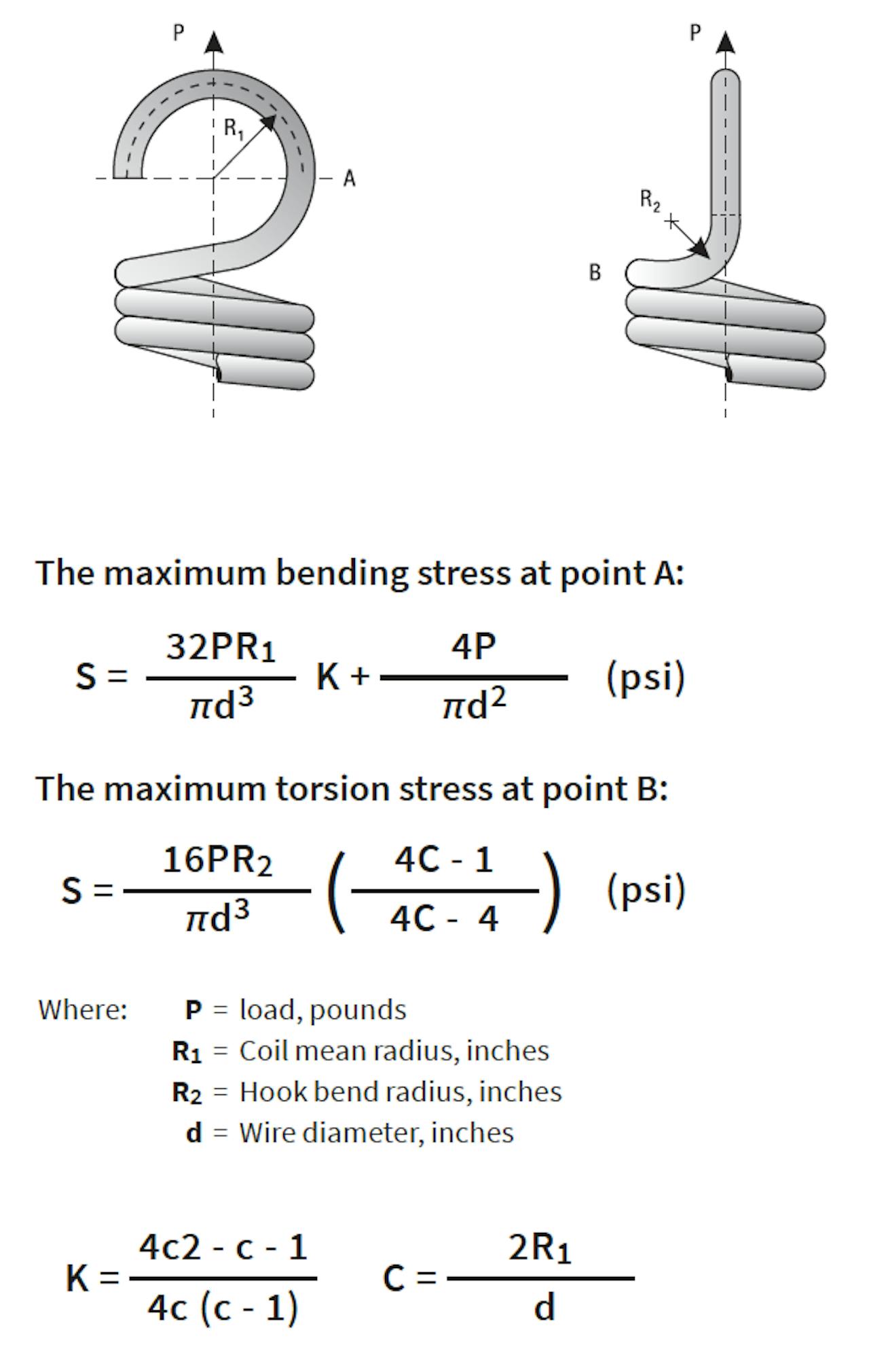

The suggested maximum-allowable stress value for an extension spring’s body wire ranges between 30 and 45 percent of the material’s minimum tensile strength (MTS). The suggested percentage values of the MTS to be used vary with the material type, and the MTS values for a given material vary with the wire diameter. Stresses in the spring hooks are normally higher than in the spring body because there is a bending stress in addition to the wire-torsion stress, specifically in the transition region between the last body coil and the hook. Therefore, an over-stressed extension spring can be expected to fail at the hook first. The suggested allowable hook stress in torsion is 30-45 percent (depending on the material) of its MTS, while that of bending is 75 percent of its MTS.

An estimate of the total stress of a common extension spring hook or loop can be determined with the information shown on the right.

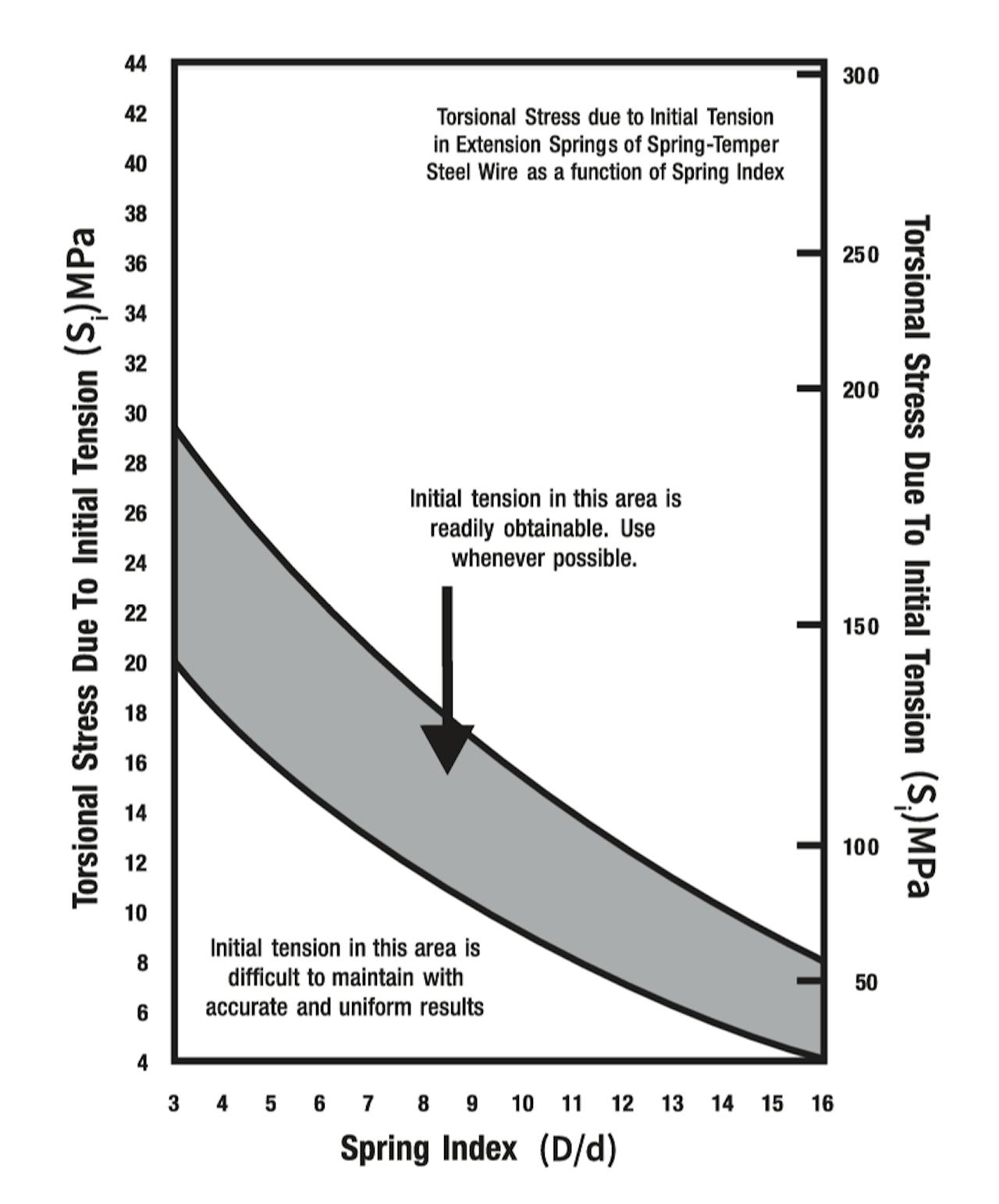

There is an increment of stress which is due to the initial tension that adds to the stress complexity; this should be accounted for in many cases. The initial tension causes the spring body to be under constant stress, which roughly varies with the spring mean diameter to wire diameter ratio. Reference the figures below for a visual representation of stress due to initial tension as well as a chart showing the Wahl curvature stress correction.

Spring Index Charts

Spring Characteristics

- Materials

Century Spring uses the highest grades of spring wire to fabricate extension springs. To create cost-effective warehousing of our stock spring inventory for our customers, we offer material certifications for custom springs only. For stock springs, we offer an optional material verification statement for a $25 fee. Certifications of conformance for geometric tolerances set by the Spring Manufacturers Institute (SMI) for our stock springs are available upon request.

“Spring Steel” is a term that includes: music wire, hard-drawn wire, and oil-tempered wire.

Stock extension springs are offered in Stainless steel 302 and 316 as specified.

- Finish

The finishes available for our torsion springs include:

- Zinc

- Gold Irridite®

- Black Oxide

- Passivated (upon request)

- None (can be plated upon request)

- Tolerances

Tolerances for extension spring rates depend upon the body-diameter to wire-diameter ratio but are usually about +/- 10% and +/- 5% on the diameter. The initial tension is much more difficult to control and is offered as a reference value only.

-

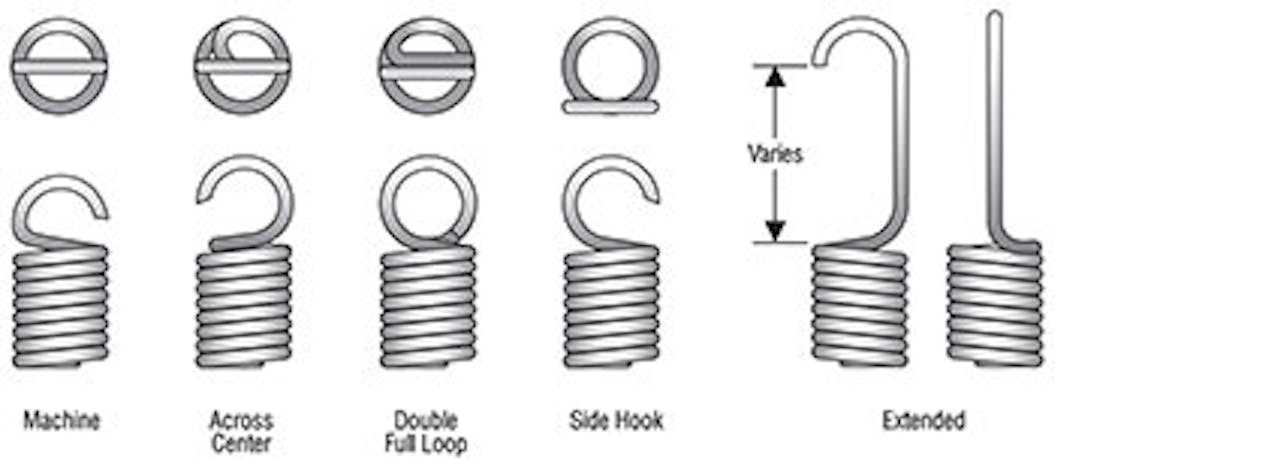

Extension Spring Ends

Extension Spring EndsThe ends on the extension springs offered in our stock inventory are the common machine-made hook and full-loop configurations. All part numbers in the 80,000s are of single-full-loop style. The hooks or loops may have an across-center transition of the last coil before forming the hook or loop (see figure here). The angle between hook/loop planes is random (end position is random).

Our stock extension spring end configurations are depicted in the figures to the right.

Contact Us

For further design and engineering resources, visit the Century Spring resource center or for specific questions related to our products or services, contact us.