Die Springs

Die Springs are specialized compression springs designed to withstand very large compression forces and extreme temperatures in highly corrosive environments. In simplest terms, they are thicker, heavier, and more structurally robust compression springs.

Die springs are exclusively used in heavy machinery and equipment such as dies and production tooling, whose primary purpose is cutting and forming metal as part of a manufacturing process line. As you can imagine, significant force is required to perform these operations. Die Springs are engineered to withstand extremely high loading (static or shock) under the most demanding metal fabrication and production environments.

However, like standard compression springs, die springs feature the same wound helical wire coil configuration that elastically deforms and shortens in length as they absorb compression loads. They are designed to achieve the same mechanical function as other compression springs- resisting the compressive forces applied at the ends of the spring and creating a force that acts opposite the direction of the die spring’s compressed coils.

Shop Die SpringsRequest a Quote

Browse More Die Springs

Browse our interactive die spring catalog to shop multiple die spring types and thousands of in-stock die springs. You can browse each type by duty load, hole diameter, spring rate, and more!

Download the spring CAD geometry before purchasing to ensure that your spring will fit your application. Place your order now and take advantage of same-day shipping!

CUSTOM MANUFACTURING

Custom Die Springs

Century Spring proudly offers state-of-the-art manufacturing equipment to produce customized die spring solutions that meet your application’s unique specifications. We have cutting-edge CNC compression self-monitoring and coiling machinery to manufacture custom sizes and styles to fit any design envelope. We also provide complete prototyping and tooling assistance services.

Whether you are in the design or procurement phase, we have the knowledge, experience, and tools to partner with you to design and manufacture the custom die springs you need.

Custom Manufacturing Capabilities

We are ready to partner with you to design a custom die spring solution that can withstand the most demanding production environments. Don’t waste another minute; reach out to one of our experts today!

Materials

Our die springs are fabricated from rectangular wire cross sections with rounded corners, the most efficient wire cross section available. Oil-tempered die springs are offered for die sets and general use at a reduced cost. For unsurpassed quality, we offer highest grade of electrically furnaced, shot-peened and preset chrome-alloy steel die springs.

Types of Die Springs

Century Spring offers multiple types of die springs with varying measurement standards. These die springs are well suited to a variety of applications, including those with high stress and heavy loads. Die springs are available in oil-tempered and chrome-alloy materials and can be custom ordered with finishes such as powder coating or nickel plating.

Color Coding - Chrome Alloy

Die springs of oil-tempered material are only available as unfinished. Chrome-alloy die springs can be custom ordered with finishes such as powder coating or nickel plating. For unfinished die springs, a color-coding system is used for visual identification of the spring’s work range and to prevent errors in spring selection and installation. The color coding is a light coating of water-based paint.

Color Coding - Chrome Silicon

Our oil-tempered die springs are unfinished. We offer a color coding system of light coating of water-based paint. A thin coating of the pain is applied to make it easy to identify your die spring's work range, helping reduce mistakes in selection and installation.

Quality Standards & Certifications

At Century Spring, we pride ourselves on creating quality products that meet or exceed industry standards. Not only do our facilities perform rigorous quality assurance testing to your specified ranges, but we also maintain several key certifications to ensure that only the best products are shipped to you.

What Our Customers Are Saying

“Terrific customer service agents who are willing to research and find the answer if not know. Nice email updates and quick product delivery.”

“I am surprised that a big company like yours would work with us little guys. And Thank You because we don't have another source for springs.”

“The website works really well, that is very important to me to find what I need quickly and accurately.”

Die Spring Information and Resources

Die Spring Characteristics

You should understand some essential die spring characteristics before you’re ready to shop.

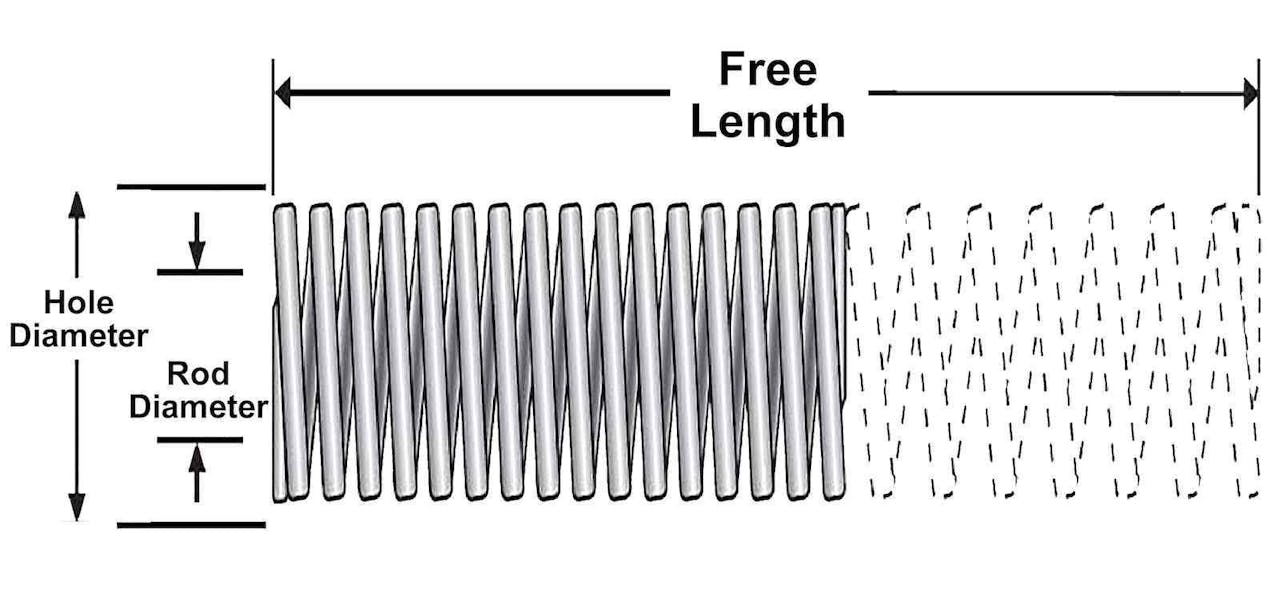

Generally, a die spring is defined by key geometric properties such as the Free Length, Hole Diameter - the dimension of the housing that the spring fits within- and Rod Diameter - the dimension of the shaft that works inside the spring. Die spring Wire Diameters are rounded-edge rectangular cross sections that are far thicker than traditional circular wire compression springs.

The die spring’s Spring Rate parameter represents the force required to compress the spring by a designated length. It is typically denoted in units of lb/in, meaning the force necessary to compress the spring by 1 in. Die spring Rates are generally much larger than standard compression spring rates.

A color system identifies unfinished die springs for easy identification in manufacturing environments. For example, for Chrome Alloy die springs, Light-Duty die springs are blue, while extra-heavy-duty die springs are Green.

How to Select a Die Spring

Recalling the key geometric characteristics introduced in the previous section is essential when shopping for die springs. However, other design characteristics of the spring, such as the duty load rating and free length, are also important.

Once you know the approximate geometry of the die spring you need, you should evaluate the load your spring will absorb. Using this design value, you can shop for die springs by their spring rates to determine the linear displacement of the spring in your application. Then, you can determine exactly how the spring will fit without your machine design when loaded and unloaded.

Check out our comprehensive die spring selection guide for more details on selecting a die spring that meets your design specifications.

Material Types and Benefits

Chrome Silicon is the most commonly specified die spring material because of its high strength and temperature resistance. It also performs very well in shock or impact loading applications, such as those seen in die tooling equipment.

However, Oil-Tempered Carbon Steel is also a great die spring option. As the name suggests, oil tempering involves heating the steel and then rapidly quenching it in oil. This fast, cost-effective heat treatment adds fatigue resistance to the spring steel and allows it to maintain strength at elevated temperatures.

However, we also offer other customized die spring materials such as Chrome alloy and additional surface finishes such as powder coating, nickel plating, and shot peening. Please contact us for a custom spring solution if you need a customized die spring material or finish.

Service Life

Generally, oil-tempered carbon steel die springs will operate for an extremely long service lifetime if the maximum spring compression is maintained under

25% of the die spring length. As such, oil-tempered springs represent an economical option for most die spring applications. However, preset Chrome silicon alloy die springs with a shot-peening surface finish will offer unmatched quality for even the most demanding die spring applications.

The chart shows how applied loads on the spring (spring stress) and temperature impact the performance of both Oil Tempered and Chromate Silicon spring steels. The “Loss of Load” represents how the spring’s performance has degraded as a function of load and temperature.

Die Spring Dimensional Measurement Guide

You can obtain all relevant die spring dimensional properties by measuring using a pair of calipers at the following locations. Take care when handling the die springs, as they are much heavier and larger than ordinary compression springs.

Wire Diameter: Place the caliper's large outside jaws on the rectangular wire at one of the spring hook ends to measure the die spring rectangular wire dimensions. Be sure to measure both the width and thickness dimensions of the wire.

Free Length: Place the caliper’s outside large jaws on the exterior ends of the die spring. Be careful not to compress the spring when taking this measurement.

Die springs are fabricated to “Go/No Go” gauge dimensions, meaning the die spring’s dimensions are specified to be slightly smaller than the mating machine dimensions in which they are designed to operate. For example, if a die spring’s Hole Diameter measures 0.96”, it is designed to fit within a 1.0” hole. Conversely, if the die spring’s Rod Diameter measurement is 0.56”, it is meant to fit over a 0.50” diameter rod.

Commonly Asked Questions About Die Springs

Do I need a custom design?

Die springs are readily available in various sizes and specifications. However, if you determine that you need a custom-designed spring that we do not carry in stock, call 800-237-5225, email, or Request a Custom Quotation today!

What material should I choose for the die spring?

Common materials for die springs include High Carbon Steel different grades of stainless steel, and other specialized non-steel alloys. Consider the corrosion resistance and your application's temperature and loading requirements.

How can I extend the life of my die spring?

To enhance the longevity of die springs:

Optimize Design: Minimize stress by choosing a die spring with larger wire diameter dimensions or investigate whether you can reduce your application’s design loads.

Material and Environmental Protection: Choose suitable materials and treatments for specific environmental conditions.

Frequency Considerations: Ensure the operating frequency is significantly lower than the spring's natural frequency to avoid resonance vibration wear and tear.

Why Choose Century Spring

Our Commitment to Quality and Service

Century Spring is a quality-first, ISO 9001 and AS9100D certified, industry-leading spring supplier specializing in stock and custom springs. We offer products and expertise to serve all vertical markets. Our experienced product engineers, knowledgeable product quality team, and skilled manufacturing personnel always deliver the highest quality products to you faster than our domestic and international competitors. All our springs are always Made in the USA.

We also feature a wide selection of available die spring sizes, from medium to extra heavy-duty load ratings. We also offer rapid turnaround, shipping, and delivery on over 40,000+ in-stock designs available to ship today. We understand your schedule constraints and are committed to getting products to you as quickly as possible.

Visit us today to learn and discover how our commitment to quality and customer satisfaction vastly improves your product design process!

Innovation and Customization in Spring Manufacturing

Century Spring offers customized spring design and fabrication services on specialized designs. Our team of highly skilled engineers is ready to help you design the perfect spring solution to meet your application's unique challenge so you can tackle your next pressing challenge. Our custom spring design, fabrication, and delivery process always has a quick turnaround so that you can minimize total product development time and receive your product precisely when you need it.

Don’t waste any more of your valuable design time today; let our spring design experts take the lead!

Get In Touch

Contact Information

Don’t stay stuck aimlessly searching for the answers to your die spring questions.

Contact Us directly today, and allow our experts to resolve all your questions and guide you to one of our in-stock die springs that fit your application. We are ready to provide comprehensive engineering support from your earliest design stages to final product approval.

Shop our Springs and Request a Quote today!

Request a Quote and Consultation

We will also help you determine if a custom die spring solution would better fit your needs. All you have to do is Request a Custom Quotation, and we will partner with you to design a custom die spring tailored to your application.

If you need immediate assistance, you can always reach us at our dedicated phone line to speak directly with our team: 800-237-5225!

Once we hear from you, our design team will follow up with a quote for a custom solution and be happy to answer any follow-up questions you may have.

Browse Other Coiled Spring Products

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.