Torsion Springs

Torsion Springs are mechanical springs that feature tightly wound wire coils that elastically unwind as they absorb torsional loads, as the name suggests. Like other springs, their primary function is to store and release energy. However, the torsion spring accomplishes this functionality by resisting forces that try to twist the spring coil into a tighter wind.

Torsion springs appear similar to tension springs on the surface, except the wire coils at each end of the spring coil, called the spring leg, are straight and protrude beyond the spring body. The legs serve to resist the torsional displacement of the application. When these ends are displaced, the spring stores energy by resisting the untwisting of the coils. When the rotational force is released, the spring returns to its previously wound place, releasing the stored energy. This way, a torsion spring will shrink slightly in body diameter and increase in length when applied load.

Some torsion springs operate cyclically, storing and releasing this torsional energy during operation, such as the simple torsion spring in wooden clothes pins. However, in other applications, the torsion spring is a continuous energy store that retains objects in a fixed position. A great example is the torsion spring designs that hold recessed ceiling lighting within their fixtures. The spring legs hold the lights by resisting the torsion of the spring and legs in the bracket.

Shop Torsion Springs Request a Quote

TORSION SPRING MANUFACTURER

Custom Torsion Springs

Century Spring proudly offers state-of-the-art manufacturing equipment to produce custom torsion springs to meet your application’s specifications by providing complete prototyping and tooling assistance services. We are equipped with cutting-edge CNC compression self-monitoring and coiling machinery to manufacture custom sizes and styles to fit any design space envelope.

We also feature a wide selection of available spring materials and surface finishes that will protect your custom torsion spring against corrosion and extreme temperature environments while increasing the functional life of your machine design.

Whether you are in the design or procurement phase, we have the knowledge, experience, and tools to partner with you to design and deliver the custom torsion springs you need.

Custom Manufacturing Capabilities

Century Spring has the in-house engineering experience and state-of-the-art manufacturing equipment to mass-produce custom torsion springs to meet your application’s specifications.

We offer various custom torsion spring geometries, including double torsion springs. We also feature a wide selection of available spring materials, and customizable surface finishes such as zinc and black oxide. These will protect your custom torsion spring against corrosion and extreme temperature environments and increase the functional life of your design.

Our custom torsion springs operate flawlessly in the most demanding environments, such as the vacuum of space!

Our engineers are ready to advise on optimal geometry, spring winding, and material and surface finish selection. Don’t waste another minute; reach out to one of our experts today!

What Our Customers Are Saying

“Terrific customer service agents who are willing to research and find the answer if not know. Nice email updates and quick product delivery.”

“The website works really well, that is very important to me to find what I need quickly and accurately.”

“I am surprised that a big company like yours would work with us little guys. And Thank You because we don't have another source for springs.”

Torsion Springs Information and Resources

About Torsion Springs

Torsion springs can store and release angular energy or statically hold a mechanism in place by deflecting the legs about the body centerline axis. They offer resistance to twist or rotationally applied force. A spring of this type will reduce in body diameter and increase slightly in body length when deflected in the preferred direction of the fabricated wind. Depending on the application, torsion springs can be designed to work in a clockwise or counter-clockwise rotation, thus determining the direction of the wind. Common torsion springs are those used in a clothes pin or a garage door.

Century Spring offers a selection of stock and standard torsion springs with legs of equal length oriented at varying unloaded angles, as well as custom torsion spring manufacturing.

Torsion Springs Characteristics

The torsion spring configuration is created for the purpose of storing and releasing angular energy or for the purpose of statically holding a mechanism in place by deflecting the legs about the body centerline axis. A spring of this type will reduce in body diameter and increase slightly in body length when deflected in the preferred direction of the fabricated wind.

The direction of the fabricated wind can also be important for torsion spring applications due to the leg bearing/attachment location having to be on the left or right side upon assembly.

A torsion spring is normally supported by a rod (mandrel) that is coincident with the theoretical hingeline of the final product.

Typical Tolerances

Tolerance values for torsion springs depend on the body-diameter to wire-diameter ratio and are about +/- 10% in torque and +/- 5% in diameter.

Century Spring: Buy Torsion Springs Online

Our Century Spring location offers custom and stock torsion springs. Stock torsion springs from Century are available for purchase online and may even be available for same-day shipping. Explore our inventory and buy now.

Torsion Spring Information and Resources

Torsion Spring Characteristics

Before shopping for a stock torsion spring, you must understand some essential characteristics.

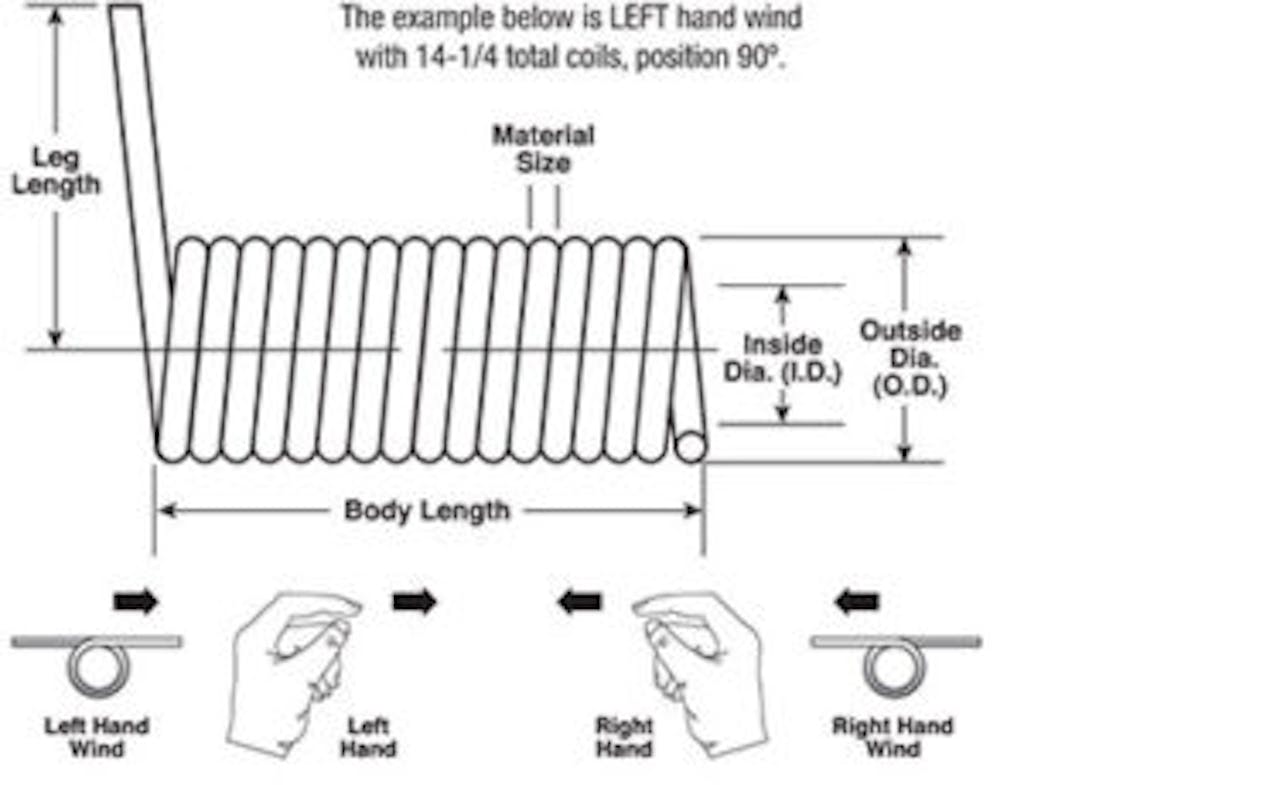

Generally, a torsion spring is defined by key geometric properties such as wire diameter, body width, leg length, Inside Diameter, angle between legs, and wind direction. The following sections will show how to measure and easily identify these parameters.

Before measuring springs, it’s important to understand another essential torsion spring characteristic called the spring rate. The spring rate is defined as the torque required to compress the two legs toward the winding direction (closing the angle) by an angular degree measurement. It is typically written in units of lb*in (torque) per degree. The torque is applied to the spring legs and the moment arms are used to calculate the applied torque.

The torsion spring rate is typically defined on a “per angle” basis, making the spring rate values very small. However, the spring rate is sometimes specified on a 360-degree basis, so it’s important to note the spring rate units carefully.

Please note the angle between the legs should be tolerance and it typically depending on the design of the spring can range from 10-5 degrees. Lastly, torsion springs are also rated according to the maximum deflection each can absorb.

Material Types and Benefits of Each

Steel is the most commonly specified material for torsion springs because its elasticity, durability, and strength make it a perfect candidate for torsion springs. There are a few different steel alloys worth mentioning so you can understand when each would be appropriate. For example, Carbon Steel springs are economical options for applications with moderate loading requirements. In contrast, Stainless Steel springs are commonly featured in applications that require corrosion resistance, such as applications found within the medical, aerospace, marine, and food industries.

Furthermore, high-carbon steel, commonly called “Music Wire,” is a specialty steel that can resist high loads due to high tensile strength. These torsion springs can withstand high stresses under repeated cyclic loading. Lastly, carbon and high-carbon steel springs can always be specified with additional surface coatings to increase corrosion resistance.

Typical Tolerances

Tolerances vary depending on the design of the spring. The Inside Diameter tolerance depends on the index of the spring, which is the ratio of the wire size to the mean diameter. The higher the index, the larger the tolerance. Also, it is important to know that as we rotate the legs, the ID of the spring becomes smaller, so be careful to have enough room for the mandrel that works inside the ID of the spring. Next would be the leg lengths. Typically the leg length tolerance is 3% of the leg length and is suggested to allow a minimum of +/- .010” for the tolerance for the shorter legs. The angle between the legs tolerance depending on the design can range from 5-10 degrees. Finally, the spring rate tolerance ranges from +/-10% to +/- 5%. If you have questions or tighter tolerances are needed, please reach out to our experienced team of engineers for guidance.

How to Select a Torsion Spring

Remember the key geometric characteristics introduced in the previous section when shopping for torsion springs. For example, the angle between the legs, the ID of the torsion spring based on the mandrel size, and the length of the legs are important properties that will determine how the spring will fit into your application and what function it will achieve.

Determining the spring rate your application may require is also necessary. The spring rate will determine the resistance the torsion spring will provide in your application. To select the correct torsion spring, you must evaluate the torque your spring will absorb from your design application. Once you know your application’s torque value, you can shop by the spring rate to determine how much angular deflection will result from the spring rate.

If you have further questions about torsion spring selection, our engineering team has compiled a comprehensive selection guide featuring detailed design information on our stock torsion springs.

Dimensional Measurement Guide

It’s important to mention that one of the critical dimensional characteristics of torsion springs is the leg configuration. The leg configuration or the angle between the legs is defined by the number of coils. For example, a spring with 5 coils is a zero-degree spring, 5.25 coils is a 90-degree spring and 5.75 coils result in a 170-degree spring. For more information please check out our guide on torsion spring angles.

You can do the following without additional equipment to obtain the following torsional spring properties.

Number of Coils: Count the total coils, beginning at one end, just under where the leg leaves the body. Continue to count coils until you reach the other end of the coil. Be sure to include any fractions of coils as well.

Wind Direction: Using the diagram as a guide, examine the spring closely to determine the direction of the coil. Springs are either denoted as left-hand wind (Clockwise) or right-hand (counterclockwise) wind.

Furthermore, you can easily obtain all additional relevant torsion spring dimensional properties of your torsion spring by using calipers to measure at the following locations:

Inside Diameter (ID): Place the caliper “teeth” on the inside diameter of the spring coils to obtain the spring’s ID.

Material Size (or Wire Diameter): Place the calipers on the wire on one of the torsion spring legs to determine the wire size of the spring.

Body Length: Place the calipers on the ends of the spring working coils near the legs to measure the spring’s body length.

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Where Torsion Springs are Used

Torsion springs are employed in countless machines across many industries, and you can find them almost anywhere if you know where to look.

They are common in diagnostic Medical Devices and Equipment, such as X-ray and MRI machines, wherever rotational motion is required.

They are engineered into dozens of safety-critical Aerospace Systems, including aerodynamic control surfaces that maintain the stability of the aircraft. The most recognizable examples are the ailerons and flaps on wings, which control the flight path of airplanes.

Torsion springs can also be found inside electronic switches and electrical contacts in Consumer Electronics.

FAQs about Torsion Springs

Do I Need a Custom Design?

Standard torsion springs are readily available in various sizes and specifications. However, if you determine that you need a custom-designed spring that we do not carry in stock, call us today at 800-237-5225, email at customquote@centuryspring.com, or fill out the custom quotation form today!

What Material Should I Choose for the Torsion Spring?

Common materials for torsion springs include music wire, different grades of stainless steel, and various alloys. Considering the corrosion resistance and your application's temperature and loading requirements is a great place to start when selecting the material.

What is a Double Torsion spring?

A double torsion spring consists of two sets of coils wound in opposite directions. One set wound clockwise and the other counterclockwise. These two coils are bridged at the middle (called the Hairpin), resisting the force by twisting nin both directions simultaneously. The total torque exerted by the spring is calculated as the sum of the torques from both coils. Century Spring offers Custom-Made double torsion springs in a variety of sizes and configurations. For more info please email us at customquote@centuryspring.com.

How can I extend the life of my torsion spring?

To enhance the longevity of torsion springs:

Optimize Design: Minimize stress by choosing a torsion spring with larger wire diameters or investigate whether you can reduce your application’s design loads.

Material and Environmental Protection: Choose suitable materials and treatments for specific environmental conditions.

Frequency Considerations: Ensure the operating frequency is significantly lower than the spring's natural frequency to avoid resonance issues.

Why Choose Century Spring

Our Commitment to Quality and Service

Century Spring is a quality-first, ISO 9001 and AS9100D certified, industry-leading spring supplier specializing in stock and custom springs. We offer products and expertise to serve all vertical markets. Our experienced product engineers, knowledgeable product quality team, and skilled manufacturing personnel always deliver the highest quality products to you faster than our domestic and international competitors. All our springs are always Made in the USA.

We offer rapid turnaround, shipping, and delivery on over 40,000+ in-stock designs available to ship today. We understand your schedule constraints and are committed to getting products to you as quickly as possible.

Visit us today to learn and discover how our commitment to quality and customer satisfaction vastly improves your product design process!

Innovation and Customization in Spring Manufacturing

Century Spring offers customized spring design and fabrication services on specialized designs. Our team of highly skilled engineers is ready to help you design the perfect spring solution to meet your application's unique challenge so you can tackle your next pressing challenge. Our custom spring design, fabrication, and delivery process always has a quick turnaround so that you can minimize total product development time and receive your product precisely when you need it.

Get In Touch

Contact Information

Don’t stay stuck aimlessly searching for the answers to your torsion spring questions.

Contact Us directly today, and allow our experts to resolve all your questions and guide you to one of our in-stock torsion springs that fit your application. We are ready to provide comprehensive engineering support from your earliest design stages to final product approval.

Shop our Springs and Request a Quote today!

Request a Quote and Consultation

We will also help you determine if a custom torsion spring solution would better fit your needs. All you have to do is Request a Custom Quotation, and we will partner with you to design a custom torsion spring tailored to your application.

If you need immediate assistance, you can always reach us at our dedicated phone line to speak directly with our team: 800-237-5225!

Once we hear from you, our design team will follow up with a quote for a custom solution and be happy to answer any follow-up questions you may have.

Browse Other Coiled Spring Products

- Compression Springs

- Extension Springs

- Die Springs

- Hot Wound Springs

- Cold Wound Springs

- Antenna Springs & Assemblies

- Garter Springs

- Tapered Springs / Barrel Springs