What is the difference between closed and closed ground ends?

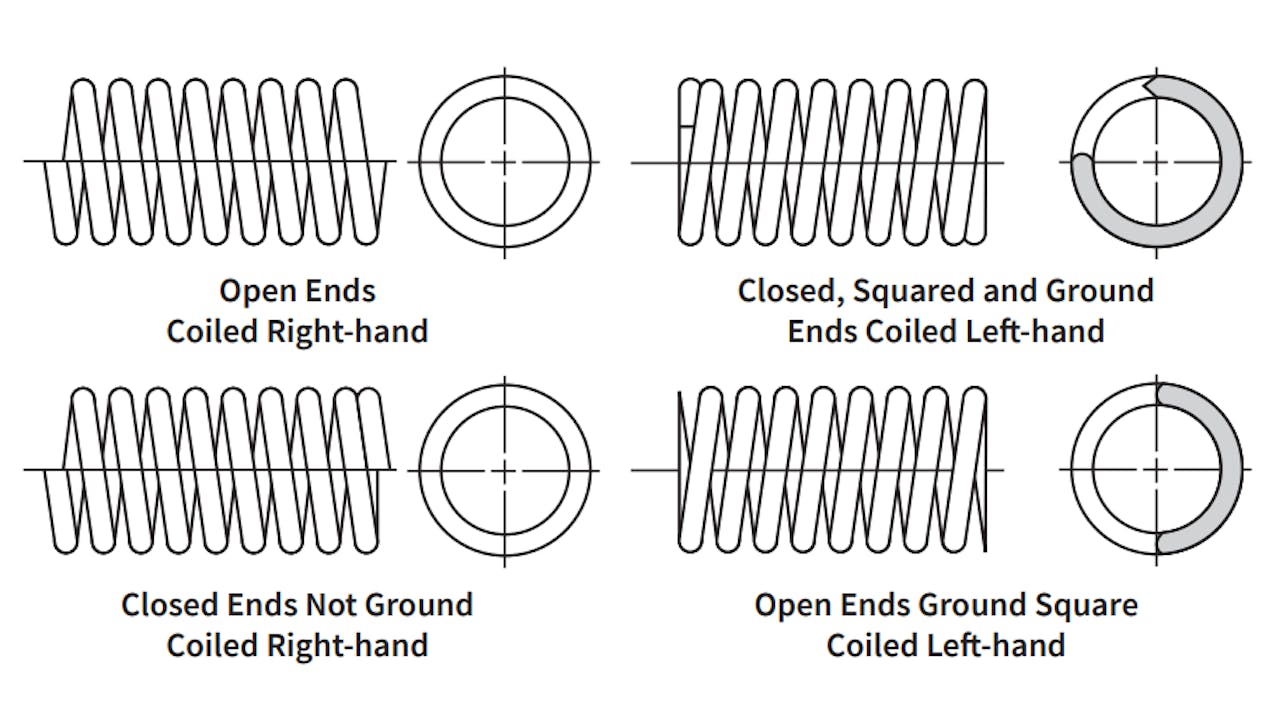

Springs can be coiled with a variety of end configurations. If the space between the coils is reduced to the point where the wire at the tip makes contact with the next coil, the end is said to be “closed”. If there is no reduction in pitch at the end coils, the end is referred to as “open”. Between these two extremes is an end type known as “semiclosed” in which the space between coils is reduced, but there is a gap between the tip and next coil. The most common configuration in industrial springs is closed ends.

An additional grinding operation may be applied to any of the end configurations listed above. Grinding removes material for the spring end coils to create a flat surface perpendicular to the spring axis. This may be done for a variety of reasons including more even distribution of the spring force to the working assembly and improved ease of assembly since the spring is more likely to stand upright unassisted (particularly with smaller index springs).

Springs can be manufactured with any of the as-coiled configurations listed below. Any of these configurations can be provided either in the ground or unground condition.

Stock springs are listed in the catalog with specific ends (C = Closed, CG = Closed & Ground or O = Open). The figure below shows schematics of both open and closed ends in both the ground and unground conditions.