How to Measure a Compression Spring

You can easily measure compression spring properties by understanding the vital geometric features and a few simple steps and tools. If you are trying to redesign or replace an existing compression spring, then it is critical that you precisely measure all relevant dimensions.

Compression springs are usually small components manufactured to tight tolerances. Precision spring manufacturing is essential because compression springs are highly engineered components that deliver reliable performance for long product lifetimes. Careful measurement of all features is critical to ensure you have the compression spring that fits and performs within your intended application. Lastly, you should also understand how each compression spring dimension impacts performance.

After we have shown you how easy it is to measure compression springs, you will be ready to shop our expansive compression spring selection of thousands of in-stock compression springs available for immediate shipping.

Essential Tools for Measuring Compression Springs

A caliper is all you need to measure compression springs. A caliper is a device used to measure linear dimensions, thickness, or diameter. Dial or digital display calipers will both work for performing the following measurements on compression springs.

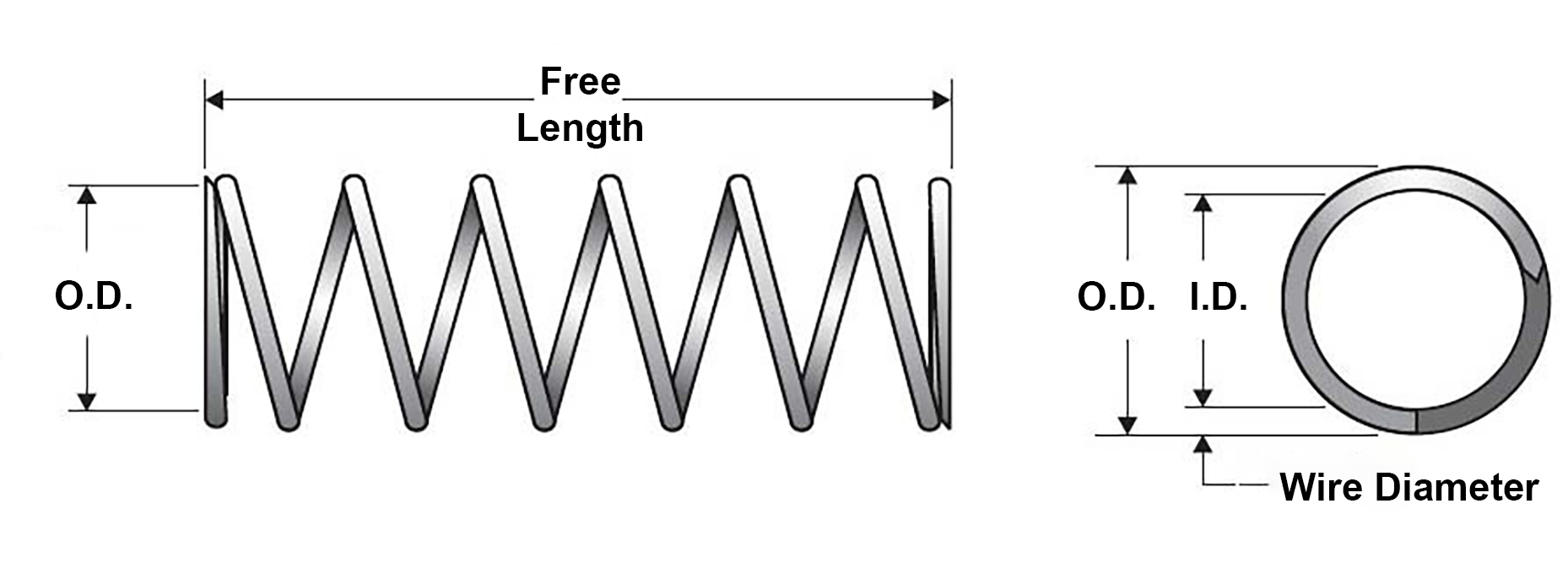

Understanding Compression Spring Dimensions

The critical dimensions of a compression spring are the following: Outer Diameter (OD), Inner Diameter (ID), Wire Diameter, Free Length, and Number of Coils.

1. Outer Diameter (OD)

The spring’s outer diameter is the diameter of the spring when measured outside the coils. It is simply the outside diameter of the helical spring coils as measured from the outside surfaces. A spring’s OD will increase slightly during compression of the spring. In simplest terms, springs with large ODs will decrease the spring rate or stiffness.

2. Inner Diameter (ID)

The spring’s inner diameter is the diameter of the coils measured from the inner surfaces of the helical coils. The inner diameter is a function of the outer and wire diameters.

3. Wire Diameter

The spring wire is the circular metal wire wound into a helical coil. As such, the wire diameter is simply a measure of the diameter of this part of the spring. The thicker the spring’s wire diameter, the larger the spring rate, meaning the more force it takes to compress the spring a given distance.

4. Free Length

A spring's free length refers to the length from top to bottom coils when the spring is uncompressed, meaning the spring does not have any load applied. Holding other spring dimensions constant, the longer the free length of the compression spring, the more total displacement the spring can absorb.

5. Number of Coils

The number of coils is simply the number of helical coils that make up the body of the compression spring. As the number of coils on a compression spring increases, the spring rate decreases, meaning it takes less force to compress the spring a given distance.

Step-by-Step Guide to Measuring a Compression Spring

Measuring the Spring’s Outer Diameter

Hold the spring on the outer surfaces between your fingers and place the outside large jaws of the caliper (the jaws with the flat surfaces on the inside) between the two surfaces. Then, use your caliper to measure this distance, which is the spring’s outer diameter (OD). Remember to use the large outside jaws on the caliper to measure all outer features.

Measuring the Wire Diameter

Locate a straight section of the compression spring that is not wound into a helical coil. Place the outside large caliper jaws around this wire, ensuring the jaws touch both sides. Take the reading from the caliper at this location. You should measure the wire diameter at both ends of the compression spring to be sure of the measurement.

Measuring the Inner Diameter

Use the inside small jaws of the caliper and insert the jaws into the spring's helical coil to measure the spring's inner diameter. You can also calculate the spring's inner diameter (ID) by subtracting twice the wire diameter from the compression spring OD.

Measuring the Free Length

Place the entire length of the uncompressed spring between the outside large jaws of the calipers and take the measurement of this location to measure the free length of the spring.

Counting the Number of Coils

Place the spring flat on its side and count the total number of coils on the spring. Be sure to include partial coils in your total count.

Tips for Accurate Spring Measurement

Before taking any measurements, be sure that the measurement surfaces on the calipers and the compression spring are clean and free of dirt and debris. Additionally, you should always take multiple measurements at several locations and average the values together to ensure consistency. Always verify that the caliper jaws are square against the measurement surfaces.

Once you have measured your spring, you can input your measurements into our compression spring calculator to calculate your spring design parameters. This tool is a fantastic design tool to help you select a spring that meets your unique design requirements.

Furthermore, compression springs naturally have a slight hourglass shape, so you may get different measurements when measuring the compression spring ID or OD at the ends versus the middle of the spring. Finally, if you need to fit a shaft into the spring or place it within a hole, you should share all dimensions with the manufacturer to ensure the spring fits into your application.

Ensure Precision with Century Spring

Century Spring is a quality-first manufacturer, so you can rest assured that every compression spring in every order meets the most rigorous design and manufacturing specifications. We specialize in stock and custom springs and offer lightning-fast fulfillment on over 40,000+ in-stock designs available to ship today!

Now that you have mastered the critical compression spring properties, you can Shop our Springs or Request a Quote today.

Don’t see the spring you need in stock? We offer custom design and fabrication services. Our highly skilled engineers will assist you in designing the perfect spring to meet your application’s unique design specifications. We always minimize development and manufacturing turnaround times so you can move on to tackle more pressing challenges. Don’t waste any more of your valuable design time- Contact Us today and let our experts take the lead!

At Century Spring, you always get the spring you need when needed! We are ISO 9001 certified, and all parts are always Made in the USA.