Compression Springs

Compression springs are marked by their distinctive helical (or corkscrew) wire configuration. Their shape allows them to absorb compression loads because as the helix compresses, the spring shortens in length and resists compressive forces.

When compressed, they efficiently store large quantities of mechanical energy, which is released upon unloading the forces that compress the helical coil.

Compression springs are found in every industry's machine components, including Aerospace, Medical, Automotive, and Consumer goods. Century Spring offers an expansive selection of in-stock compressive springs available to ship today. We also have the expertise to design and manufacture custom compression springs to fit any mechanical application across the most demanding industries.

Browse More Compression Springs

Shop thousands of in-stock compression springs for sale using our spring catalog. Browse by material, size, finish, and more! Rest easy knowing that your spring will fit your application by downloading the spring CAD before purchasing!

Place your order now and take advantage of same-day shipping!

The World's Largest Selection of Stock Springs, Plus Custom Build-to-Spec

Century Spring offers the most extensive selection of stock springs. We are equipped with cutting-edge CNC self-monitoring, coiling machinery that enables the production of custom sizes and styles. This includes but is not limited to variable pitch springs and large compression springs. We also provide spring design & prototyping assistance. Our team's expertise and experience, coupled with our comprehensive toolset, are ready to support your project, no matter your stage in the design or production process.

Compression Spring Calculator

Instant design data based on your spring properties.

Custom Compression Springs

Custom Manufacturing Capabilities

We offer engineering experience and state-of-the-art manufacturing equipment to produce custom compression springs to meet your application’s specifications. We feature a wide selection of available spring materials and surface finishes that will protect your custom compression spring against corrosion and extreme temperature environments while increasing the functional life of your machine design.

Material

- Carbon Steel

- Chrome Silicon

- Hastelloy®

- Inconel®

- Monel

- Music Wire

- Stainless Steels (302/304, 316, & 17-7)

Finishes

- Black Oxide

- Passivation

- Powder Coating & Color Coding

- Rubber

- Plating (Zinc, Nickel, Silver, Tin & Gold Electroplating)

Wire Sizes & End Types

- Cold Coiled Wire Sizes: 0.002″ – 0.75″

- Hot Wound Wire Sizes: 0.625″ – 3.00″

- Open Ends

- Closed Ends

- Closed & Ground Ends

What Our Customers Are Saying

“Easy to use website. Great customer service.”

“We are very pleased with our service. My emails are responded to promptly & lead times are pretty much spot on.”

“It was very easy to check stock and pricing.”

Understanding Compression Spring Specifications and Materials

How to Select a Compression Spring

Our engineering team has compiled a comprehensive, compression spring selection guide featuring detailed design information on the stock compression springs we offer.

Material Types and Benefits of Each

Steel springs are the most common compression springs because their elasticity, durability, and strength make them perfect candidates for mechanical springs. Carbon Steel springs are an economical choice for applications with moderate loading requirements, while Stainless Steel springs are commonly found in wet applications that require corrosion resistance within the medical, aerospace, marine and food industries.

Furthermore, high-carbon steel, commonly called “music wire,” is a specialty steel that can resist high loads due to high tensile strength. It withstands higher stresses under repeated loading with great fatigue life. This material can also be easily plated. Check out our catalog for other available compression springs.

Load and Compression Rate Explained

Spring Rate is formally defined as the load required to compress the spring 1.0 inch, typically measured in pounds (lb/in). It is determined by the spring’s wire diameter, the number of coils, and the diameter of its helical coils.

The larger the force required to compress the spring a given distance, the larger the spring rate. For example, a spring with a spring rate of 20 lb/in requires 20 lb of force to compress the spring 1.0 in.

To illustrate the principle of spring rate further, engineers design with a known load that the spring must be able to absorb. Machine designs typically have tight space or deflection envelopes in which the spring must operate. As a design engineer, you can use the spring rate on a particular spring and the geometry to calculate the deflection under design loading conditions. This information lets you easily determine whether such a spring will meet your space envelope design requirements and allowable deflection envelope.

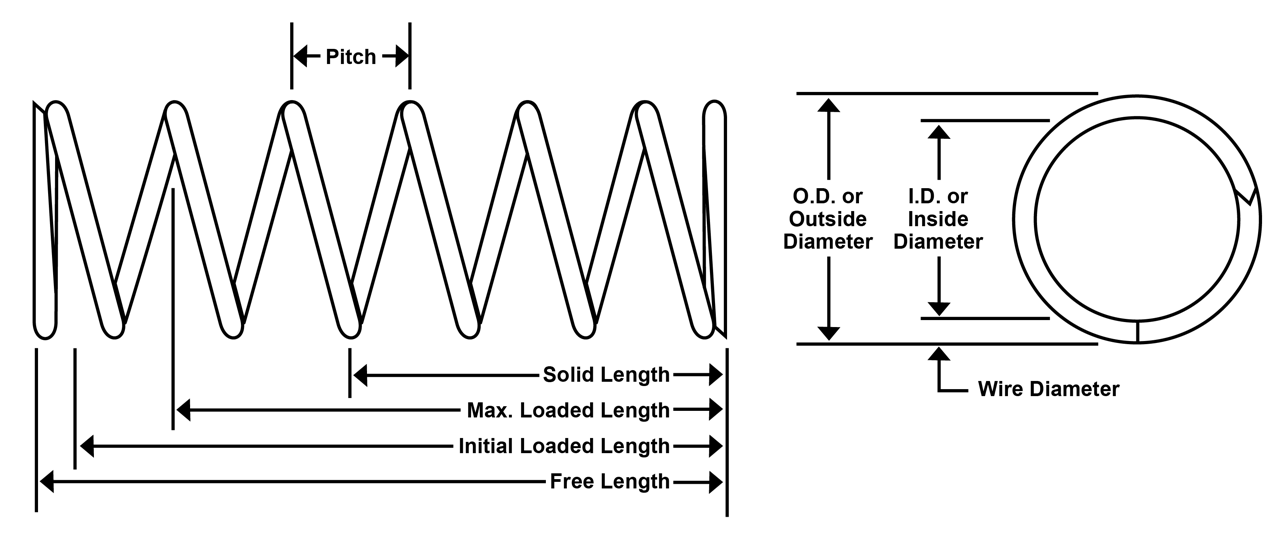

Dimensions Measurement Guide

You can easily obtain all of the relevant dimensional properties of your compression spring by using calipers to measure at the following locations:

- Hold the spring on the outer surfaces between your fingers and use calipers to measure the outside of the coil to measure the compression spring's Outside Diameter (O.D.).

Use your calipers to measure the wire that forms the helical shape of the compression spring. This is called the Wire Diameter. You should measure the wire diameter at both ends of the spring to be certain of the measurement.

- Place the entire length of the uncompressed spring between your calipers to measure the Free Length of the spring.

- Place the spring flat on its side and count the total number of coils on the spring. Be sure to include even coil portions in your total count. (See the diagram for an example). This number is called the Total Coils.

Try our Spring Calculator to automatically get key design data based on your spring’s measurements.

Commonly Asked Questions About Compression Springs

Do I Need a Custom Design?

Standard compression springs are readily available in various sizes and specifications. However, if you determine that you need a custom-designed spring that we do not carry in stock, call us today at 800-237-5225 email us at customquote@centuryspring.com, or fill out our custom quote form today!

What Material Should I Choose for the Compression Spring?

Common materials for compression springs include music wire, different grades of stainless steel, and various alloys. Considering the corrosion resistance and your application's temperature and loading requirements is a great place to start when selecting the material.

How can I extend the life of my compression spring?

To enhance the longevity of compression springs:

Optimize Design: Use larger wire diameters or lower final loads to minimize stress.

Shot Peening and Pre-Setting: Apply these techniques to increase durability and fatigue life.

Material and Environmental Protection: Choose suitable materials and treatments for specific environmental conditions.

Frequency Considerations: Ensure the operating frequency is significantly lower than the spring's natural frequency to avoid resonance issues.

Century Spring Catalog

From compression springs and extension springs to retaining rings, the Century Spring catalog contains details on thousands of parts available for same-day shipping. Download the catalog now or contact us to request a physical copy.

Why Choose Century Spring

Our Commitment to Quality and Service

Century Spring is a quality-first, ISO 9001: 2015 and AS9100D certified, industry-leading spring supplier specializing in stock and custom springs. We offer products and expertise to serve all vertical markets. Our experienced product engineers, knowledgeable product quality team, and skilled manufacturing personnel always deliver the highest quality products to you faster than our domestic and international competitors.

We offer rapid turnaround, shipping, and delivery on over 40,000+ in-stock designs available to ship today. We understand your schedule constraints and are committed to getting products to you as quickly as possible.

Visit us today to learn and discover how our commitment to quality and customer satisfaction vastly improves your product design process!

All parts are always Made in the USA.

Innovation and Customization in Spring Manufacturing

Century Spring offers customized spring design and fabrication services on specialized designs. Our team of highly skilled engineers is ready to help you design the perfect spring solution to meet your application's unique challenge so you can tackle your next pressing challenge. Our custom spring design, fabrication, and delivery process always has a quick turnaround so that you can minimize total product development time and receive your product precisely when you need it.

Don’t waste any more of your valuable design time today; let our spring design experts take the lead!

Get in Touch

Contact Information

Don’t stay stuck aimlessly searching for the answers to your compression spring questions.

Contact Us directly today, and our experts will resolve all your questions immediately and guide you to the compression spring that will perfectly fit your application. We offer comprehensive engineering support from your earliest design stages to final product approval.

Shop our Springs and Request a Quote today!

Request a Quote and Consultation

If you know that a custom spring is what you need to meet your application’s demands, you can be better suited for your application. You can Request a Custom Quotation by filling out a short form. Our design team will reach out to you quickly with a quotation and be able to answer any follow-up questions you may have.

You can always reach us at our dedicated phone line to speak directly with our team: 800-237-5225!

Related Products and Services

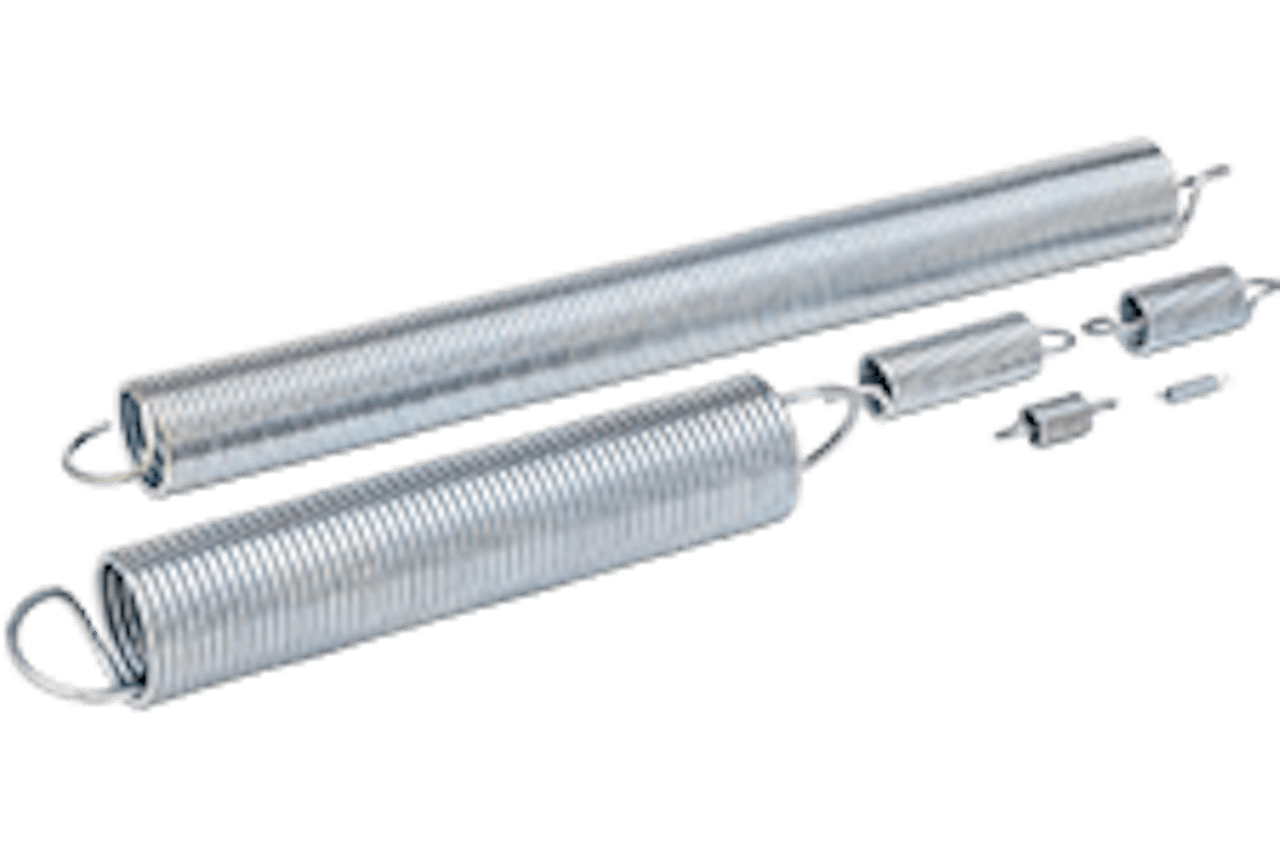

Extension Springs

Extension Springs are designed to resist tension forces. These springs are similar to compression springs, except their coils are wound tighter because they are designed to be extended during operation. Extension springs absorb mechanical energy as the coils separate.

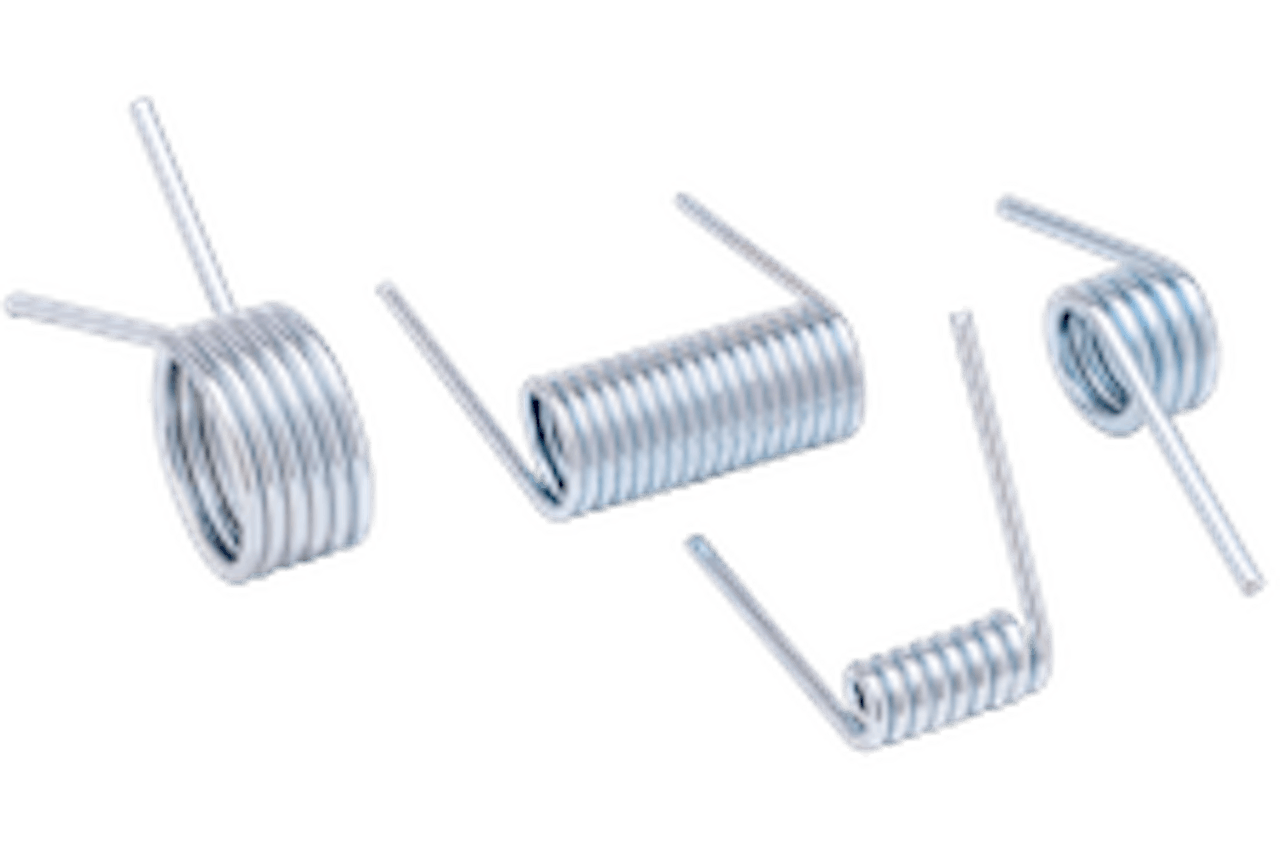

Torsion Springs

Torsion Springs are engineered to resist twisting forces, as the name suggests. They are tightly wound wire coils that elastically unwind as they absorb torsional loads.

Stock Torsion Springs are available in body lengths up to 3.8” in steel, stainless steel, and music wire materials with multiple available surface finishes.

Shop In-Stock Springs

We have millions of parts in stock with over 40,000 unique spring designs that ship the same day you order. Whether you need a compression spring, extension spring, or urethane spring, we have the part you need.

Request a Custom Spring

Century Spring can handle custom orders as small as one part or large production runs in the millions. We'll even provide design for manufacturability support to help reduce your costs and time to market.