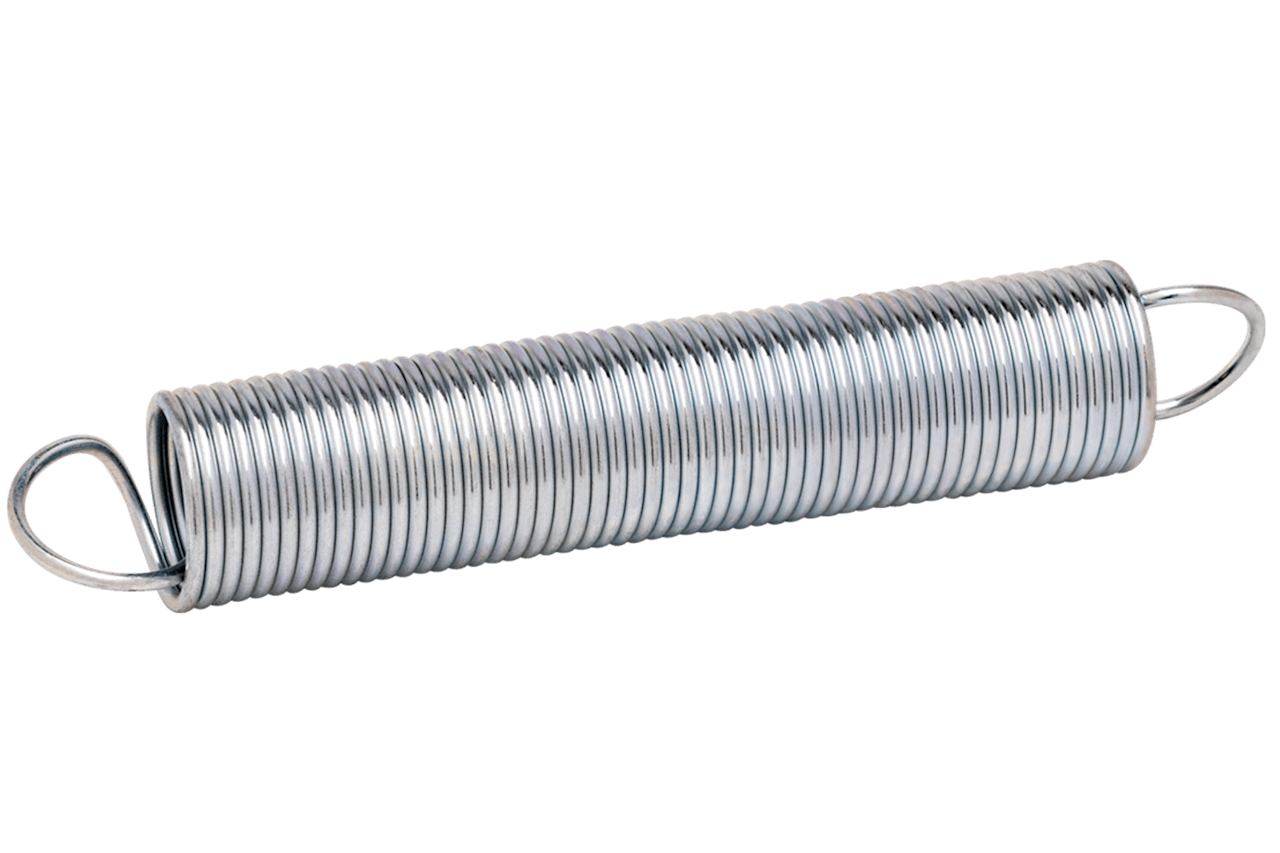

Extension Springs

Extension Springs are mechanical springs that feature tightly wound helical wire coils that elastically deform as they absorb tension loads. As the name suggests, these tension loads cause the spring to extend in length. Like other springs, their primary function is to store and release energy by resisting the external pulling forces applied to the spring ends. This resistance stores energy and creates a force that acts opposite the direction of the spring extension.

As such, extension springs are attached to components that move away from each other. The extension releases the stored energy to bring the components back together. Observing extension springs in consumer products like trampolines allows you to visualize this mechanical action. Under loading, the extension springs around the perimeter of the trampoline and then produces a counterforce upon unloading that propels the trampoline mat upward.

Browse More Extension Springs

Browse our interactive extension spring catalog to shop for thousands of in-stock extension springs available today. You can browse by material, size, finish, and more!

Download the spring CAD geometry before purchasing to ensure your spring will fit your application. Place your order now and take advantage of same-day shipping!

Custom Extension Springs

Century Spring proudly offers state-of-the-art manufacturing equipment to produce customized extension springs that meet your application’s specifications. We provide complete prototyping and tooling assistance services. We have cutting-edge CNC compression self-monitoring and coiling machinery to manufacture custom sizes and styles to fit any design envelope.

We also feature a wide selection of available spring materials and surface finishes that will protect your extension springs against corrosion and extreme temperature environments while increasing the functional life of your machine design.Whether you are in the design or procurement phase, we have the knowledge, experience, and tools to partner with you to design and manufacture the custom extension springs you need.

Ready to get started? Request a Quote.

Custom Extension Springs

Custom Manufacturing Capabilities

Century Spring has the in-house engineering experience and state-of-the-art manufacturing equipment to mass-produce custom extension springs to meet your application’s specifications.

We offer custom extension spring geometries, wire diameters, and end configurations. We can design and fabricate custom springs from specialized materials, including stainless steel, high-carbon steel, and nickel alloys. We can apply numerous surface finishes, such as Zinc, Black Oxide, and Gold Iridite, to achieve additional corrosion resistance.

We are ready to partner with you to design an extension spring solution that can withstand the most demanding applications. Our custom spring solutions operate continuously under high loading in extreme environments, such as the vacuum of space.

Our engineers are ready to advise on optimal geometry, spring winding, and material and surface finish selection. Don’t waste another minute; reach out to one of our experts today!

Material

- Beryllium Copper

- Bronze

- Hastelloy®

- Inconel®

- Monel

- NiSPAN-C®

- Stainless Steels

- Steel (including: Chrome Silicon & Chrome Vanadium)

- Tantalum

- Titanium (Beta-C)

Finishes

- Black Oxide

- Color Coding

- Gold Irridite

- Nickel

- Passivation

- Plating

- Powder Coating

- Silver

- Tin

- Zinc

Wire Types

- Wire and Bar Stock: 0.008" - 0.750"

Direction of Helix (Wind)

- Left

- Right

What Our Customers Are Saying

“Terrific customer service agents willing to research and find the answer if not know. Nice email updates and quick product delivery.”

“I am surprised that a big company like yours would work with us little guys. And Thank You because we don't have another source for springs.”

“The website works really well, that is very important to me to find what I need quickly and accurately.”

Extension Spring Information and Resources

Extension Spring Characteristics

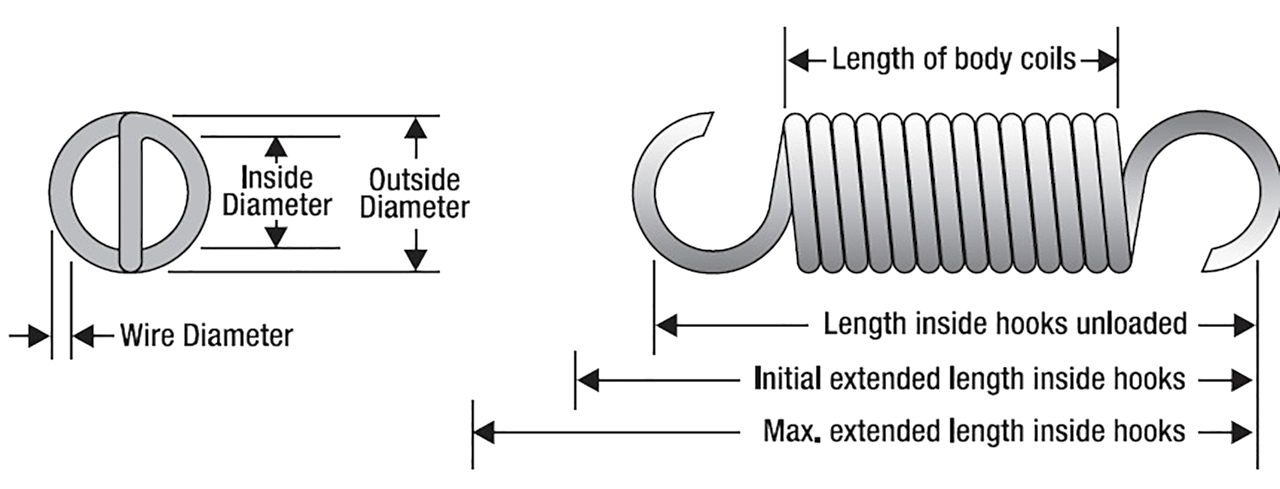

You should understand some essential extension spring characteristics before you’re ready to shop. Generally, an extension spring is defined by key geometric properties such as the Wire Diameter, Outside Diameter (OD), and Length inside Hooks (LIH).

The extension spring’s Spring Rate parameter represents the force required to extend the extension spring by a designated length unit. It is typically denoted in units of lb/in, meaning the force required to extend the spring by 1 in. Furthermore, the extension spring’s initial tension is the tension (measured in lb.) accumulated between the extension springs' coils when the spring is unloaded. It is the force needed to move a helical coil just enough to observe light passing through the coils.

How to Select an Extension Spring

Recalling the key geometric characteristics introduced in the previous section is essential when shopping for extension springs. However, other design characteristics of the spring, such as the extension spring's maximum deflection and maximum load capacity, are also important considerations because they determine the spring’s functionality in operation.

Once you know the approximate geometry of the extension spring you need, you should evaluate the load your spring will absorb. Using this design value, you can shop for extension springs by their Spring Rates to determine the linear displacement of the spring in your application. Then, you can determine exactly how the spring will fit without your machine design when loaded and unloaded.

Check out our comprehensive extension spring selection guide for more details on selecting an extension spring that meets your design specifications.

Material Types and Benefits

Steel is the most commonly specified spring material because its elasticity, durability, and strength make it a perfect candidate for extension springs. There are a few different steel alloys worth mentioning so you can understand when each would be appropriate.

For example, carbon steel springs are economical options for applications with moderate loading requirements. In contrast, stainless steel springs are commonly used in applications requiring corrosion resistance, such as those in the medical and aerospace industries.

Furthermore, high-carbon steel is a specialty steel that can resist high loads under cyclic loading due to its high tensile strength. Extension springs can usually be specified with additional surface coatings to increase corrosion resistance.

Check out our full spring material guide for more information on spring materials.

Typical Tolerances

Extension Spring dimensional tolerances vary depending on the extension spring, but generally, they range from approximately +/-10% to +/-5%.

The spring’s OD tolerance is a function of the spring index, which is the ratio of the wire size to the spring’s mean diameter. In simplest terms, the larger the spring index, the larger the tolerance range on the spring’s dimensions. Also, you should expect larger tolerance ranges for increased extension spring LIH dimensions.

Custom extension springs can be specified with tighter dimensional tolerances, such as the extension spring rate, which can be manufactured to a tighter +/- 5% tolerance value. Other dimensions with custom tolerance ranges specified are the extension spring hook gap and hook end position.

If you have questions or need a spring designed for a tighter tolerance, contact our experienced team of engineers.

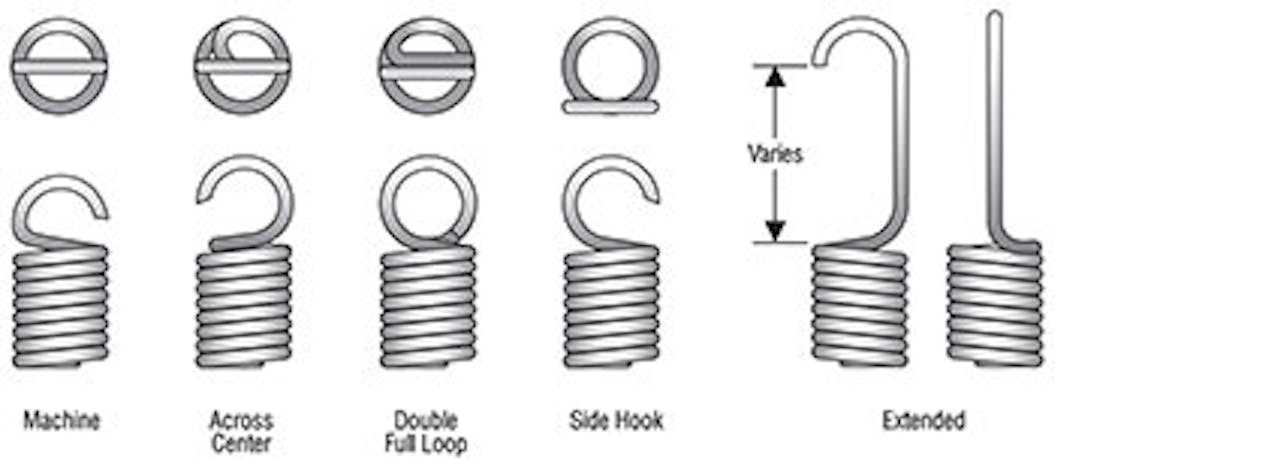

Extension Spring Ends

An extension spring's ends are usually either hook or full-loop configurations. However, additional configurations, such as the double full loop, across center, side hook, and extended configurations, are available.

You can contact us anytime for a custom end configuration with controlled dimensions. We will work with you to design an end configuration that fits your intended application.

Extension Spring Dimensional Measurement Guide

You can quickly obtain all additional relevant extension spring dimensional properties by measuring using a pair of calipers at the following locations.

Outside Diameter (OD): Place the caliper's large outside jaws on the outside diameter of the spring's helical coils to measure the spring’s OD.

Wire Diameter: Place the caliper's large outside jaws on the wire at one of the spring hook ends to determine the spring’s Wire Diameter.

- Length inside Hooks (LIH): Place the caliper’s inside small jaws on the interior of the hooks on each end of the spring. Take care not to extend the spring when you are taking the measurement. This measurement represents the entire enveloping length of the extension spring.

Applications and Industries

Where Extension Springs Are Used

Extension springs are employed in countless machines across many industries, and if you know where to look, you can find them almost anywhere.

They are common in diagnostic medical devices, such as stretchers, surgical lifts, and certain surgical equipment.

They are engineered into safety-critical aerospace components, such as landing gear assemblies.

You can find them in specialized automotive equipment, such as carburetors.

They are also present in several nicheconsumer electronics products, such as retractable power cord mechanisms.

Commonly Asked Questions About Extension Springs

Do I need a custom design?

Standard extension springs are readily available in various sizes and specifications. However, if you determine that you need a custom-designed spring that we do not carry in stock, call 800-237-5225, email, or Request a Custom Quotation today!

What material should I choose for the extension spring?

Common materials for extension springs include music wire, different grades of stainless steel, and other specialized non-steel alloys. Consider the corrosion resistance and your application's temperature and loading requirements.

How can I extend the life of my compression spring?

To enhance the longevity of extension springs:

Optimize Design: Minimize stress by choosing an extension spring with the right wire diameters or investigate whether you can reduce your application’s design loads.

Material and Environmental Protection: Choose suitable materials and treatments for specific environmental conditions.

Frequency Considerations: Ensure the operating frequency is significantly lower than the spring's natural frequency to avoid resonance vibration wear and tear.

Why Choose Century Spring

Our Commitment to Quality and Service

Century Spring is a quality-first, ISO 9001 and AS9100D certified, industry-leading spring supplier specializing in stock and custom springs. We offer products and expertise to serve all vertical markets. Our experienced product engineers, knowledgeable product quality team, and skilled manufacturing personnel always deliver the highest quality products to you faster than our domestic and international competitors. All our springs are always Made in the USA.

We offer rapid turnaround, shipping, and delivery on over 40,000+ in-stock designs available to ship today. We understand your schedule constraints and are committed to getting products to you as quickly as possible.

Visit us today to learn and discover how our commitment to quality and customer satisfaction vastly improves your product design process!

Innovation and Customization in Spring Manufacturing

Century Spring offers customized spring design and fabrication services on specialized designs. Our team of highly skilled engineers is ready to help you design the perfect spring solution to meet your application's unique challenge so you can tackle your next pressing challenge. Our custom spring design, fabrication, and delivery process always has a quick turnaround so that you can minimize total product development time and receive your product precisely when you need it.

Don’t waste any more of your valuable design time today; let our spring design experts take the lead!

Get In Touch

Contact Information

Don’t stay stuck aimlessly searching for the answers to your torsion spring questions.

Contact Us directly today, and allow our experts to resolve all your questions and guide you to one of our in-stock torsion springs that fit your application. We are ready to provide comprehensive engineering support from your earliest design stages to final product approval.

Shop our Springs and Request a Quote today!

Request a Quote and Consultation

We will also help you determine if a custom torsion spring solution would better fit your needs. All you have to do is Request a Custom Quotation, and we will partner with you to design a custom torsion spring tailored to your application.

If you need immediate assistance, you can always reach us at our dedicated phone line to speak directly with our team: 800-237-5225!

Once we hear from you, our design team will follow up with a quote for a custom solution and be happy to answer any follow-up questions you may have.

Related Coiled Spring Products

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.