Urethane Springs

Urethane springs are compression springs with a completely different appearance than a typical metallic wire helical coil compression spring. These springs are fabricated from a polyether elastomer material and feature a small hole in the center. This material reacts in compression very similarly to an incompressible fluid. Under compression, the sides of urethane springs bulge like you would expect a fluid volume to move. Urethane springs are cylindrical with a small through-hole in the center.

Urethane springs are compression springs designed for use where employing a traditional metallic helical coil spring is impossible, such as in applications with magnetic fields or significant vibrational loads.

In such applications, a urethane compression spring would outperform a metallic helical coil spring, and they have proven themselves to be safe, reliable, and efficient spring options in such applications.

The World's Largest Selection of Stock Springs, Plus Custom Build-to-Spec

Custom Urethane Spring Manufacturing Capabilities

Custom urethane spring options include length, diameter, and rated durometer.

We partner with you to determine the urethane spring design that will meet your application’s requirements, such as temperature resistance or load-carrying capability. We offer state-of-the-art manufacturing equipment backed by world-class spring design expertise to mass-produce custom urethane springs.

We also offer several in-house pre-production services, including CAD modeling, Prototyping, and Production Tooling creation to ensure that every urethane compression spring meets your performance requirements.

Whether you are in the design or procurement phase, we have the knowledge, experience, and tools to bring your project to life.

Urethane Springs: Information & Resources

Urethane Spring Characteristics

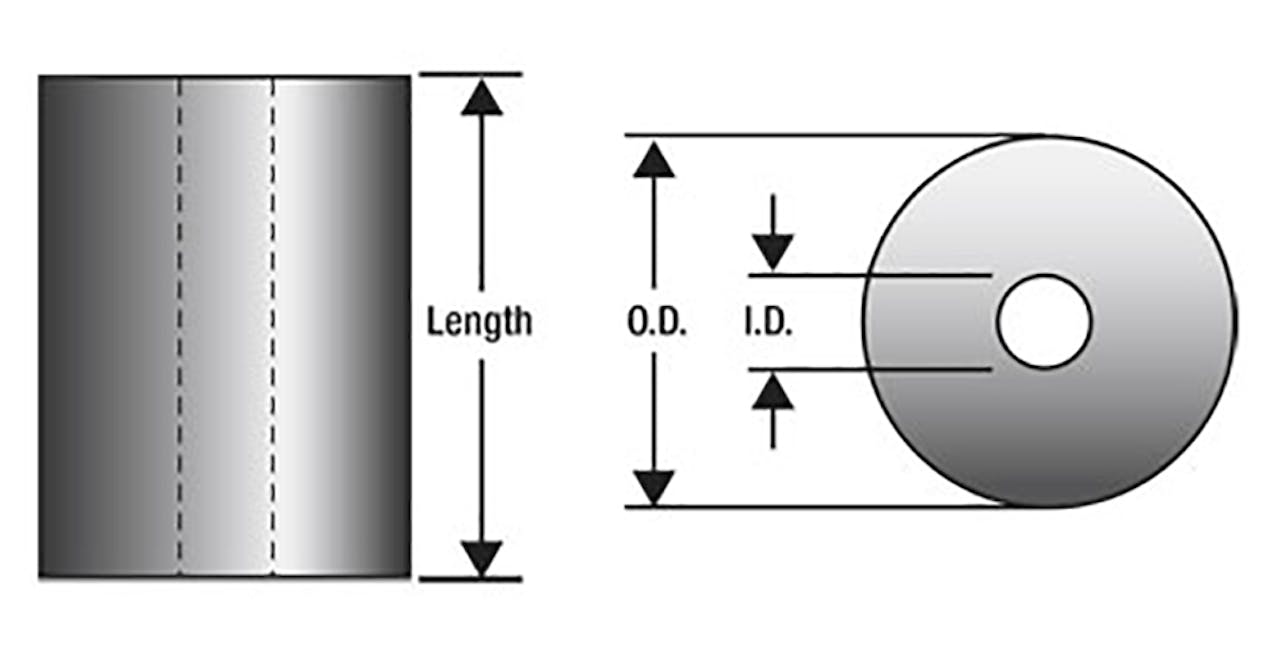

Notable urethane compression spring geometric characteristics include the following:

Outside Diameter: This is the outer diameter of the cylindrical urethane spring when it is unloaded.

Free Length: This is the length of the spring when it is unloaded. A urethane spring's recommended maximum free length is 2.5 times its outside diameter. However, springs can be stacked on top of each other in series or separated by cylindrical washers.

Inside Diameter: This is the diameter of the hole in the middle of the urethane spring.

Durometer: This is a measure of the hardness of the urethane/ polyether-elastomer material

Century Spring’s Urethane springs are fabricated from a unique polyether-elastomer material that is not rigid or brittle like other plastics. This material behaves like a fluid when displaced. For example, as the length of the spring decreases under compression, the diameter increases by a proportional amount, preserving the spring's total volume.

For example, if a spring is compressed by 15%, its diameter will increase by 15%. Your machine design should account for this increase in the lateral diameter of the urethane spring.

Benefits of Urethane Springs

Urethane springs feature excellent elasticity and material resilience under high-load applications.

In general, when compared to traditional metallic wire helical coil compression springs, Urethane springs offer the following mechanical advantages:

High load-carrying capability

Non-Magnetic

Excellent electrical insulator- (e.g., High Dielectric Strength)

Excellent resistance to galling

Abrasion resistance

Oil and solvent resistance

Operates with low noise level

Excellent vibration damping

Excellent shock absorption

Bondable surface

Reliable operation over long product lifetimes

However, compared to metallic compression springs, urethane springs have poor heat resistance and should not be used at temperatures below -30°F or above 180°F. Additionally, if urethane springs are overloaded repeatedly, they are vulnerable to creep failure, a failure mode in which small cracks under compressive load and eventually rupturing spring.

How to Select a Urethane Spring

You should recall the key geometric characteristics introduced in the previous section when shopping for urethane springs. You should also consider the temperature requirements of your application to ensure that a urethane spring is appropriate.

Once you know the approximate geometry of the urethane spring you need and that it will fit, you should evaluate the operational deflection compared to the maximum value.

To do this, you can shop for urethane springs using their Shore Durometer to obtain an approximation of the linear displacement of the spring and the increase in diameter under compression in your application. Common urethane spring durometers are measured in the Shore A scale (i.e., the softest scale) 60A, 80A, 90A, and 95A, where a higher number indicates increasing hardness. For example, an automotive tire tread has a durometer of 70A, while the comparatively harder wheels on a skateboard have a durometer of 90A

In general, the maximum deflection of urethane springs decreases with shore durometer. For example, a 95A urethane spring’s maximum deflection is 25% of the spring's free length, while a 70A urethane spring’s maximum deflection is 60%.

With this information, you can quickly determine how your urethane spring will fit within your machine design when loaded and unloaded.

Urethane Spring Capabilities

| Pounds to Produce 1/8" Deflection | |

|---|---|

| Conventional heavy-duty die spring | Up to 500 lbs |

| Urethane springs | Up to 2,600 lbs |

| Urethane bar stock | Up to 90,000 lbs |

| Urethane slab stock | Unlimited |

Cyclic Frequency & Deflection

Suggested maximum cyclic frequency and deflection percentage of free length

| Maximum Deflection | Cycles Per Hour | |

|---|---|---|

| Slow speeds / short runs | less than 25% | 200 |

| Intermittent | up to 25% | 700 |

| Continuous | up to 15% | 12,000 |

Applications and Industries

Where Urethane Springs Are Used

Urethane compression springs are extremely versatile and can be used in countless machine designs and industries. If environmental factors allow, they can be specified in place of helical coil compression springs.

Urethane springs are most commonly used in high-impact manufacturing equipment such as die-cutting and metal stamping machines where reliability and vibration resistance are needed.

They are also found in automotive equipment, such as suspension and clutch systems within the engine transmission.

Heavy machinery found in construction and agriculture employs urethane springs.

CUSTOM MANUFACTURING

Custom Urethane Springs

Century Spring specializes in custom component manufacturing and offers many added production features, including design and tooling assistance as well as prototyping and performance testing. Contact us for more information on how we can customize the right part for your preferred application.

FAQs About Urethane Springs

Do I need a custom design?

We have many varieties of urethane springs readily available. If you need a custom-designed spring, call 800-237-5225, Email, or Request a Custom Quotation today!

Why Choose Century Spring

Our Commitment to Quality and Service

Century Spring is a quality-first, ISO 9001 and AS9100D certified, industry-leading spring supplier specializing in stock and custom springs. We are the most trusted name in spring manufacturing and offer products and expertise to serve all vertical markets.

Our experienced product engineers, knowledgeable product quality team, and skilled manufacturing personnel always deliver the highest quality products to you faster than our domestic and international competitors. All our springs are always Made in the USA.

We offer rapid delivery on over 40,000+ in-stock designs available to ship today. We understand your schedule constraints and are committed to getting products to you as quickly as possible.

Visit us today to discover how our commitment to quality and customer satisfaction vastly improves your product design process!

Advances and Personalized Solutions in Spring Production

Century Spring offers customized spring Design and Manufacturing Services for specialized spring and spring anchor solutions. Our team of highly skilled engineers is ready to help you design the perfect spring anchor solution to meet your application's unique challenge so you can tackle your next pressing challenge.

We always strive for fast turnaround on all of our custom spring design, fabrication, and delivery services so that you can minimize total product development time and receive your product precisely when needed.

Don’t waste any more of your valuable design time today; let our spring design experts take the lead!

What Our Customers Are Saying

“Terrific customer service agents who are willing to research and find the answer if they don't know. Nice email updates and quick product delivery.”

“I am surprised that a big company like yours would work with us little guys. And Thank You because we don't have another source for springs.”

“The website works really well, that is very important to me to find what I need quickly and accurately.”

Get In Touch

Contact Information

Contact Us directly today, and allow our experts to resolve all your questions and guide you to one of our in-stock spring anchors that will fit your application. We are ready to provide comprehensive engineering support from your earliest design stages to final product approval.

Request a Quote and Consultation

We will also help you determine if a custom anchor spring solution better suits your needs. All you have to do is Request a Custom Quotation, and we will partner with you to design a spring anchor tailored to your application.

Once we hear from you, our design team will follow up with a quote for a custom solution and be happy to answer any follow-up questions you may have.

If you need immediate assistance, you can always reach us at our dedicated phone line to speak directly with our team: 800-237-5225.

Related Spring Products

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.